NEW AERODINAMICA SRL

Via S.L. in Cavellas, 21

24060 Casazza (BG)

Tel. +39 035 81 04 08

info@newaerodinamica.com

www.newaerodinamica.com

Facebook: www.facebook.com/newaerodinamica

Instagram: www.instagram.com/newaerodinamica

Linkedin: www.linkedin.com/company/new-aerodinamica-srl

Youtube: www.youtube.com/user/newaerodinamica

MANAGEMENT

Paolo Radaelli, CEO

BUSINESS SECTORS

Machines and equipment for printing & converting

PRODUCT RANGE

Design and construction of customized and complete trimmings, waste and dust extraction systems.

THE INTERVIEW

Paolo Radaelli

CEO

In today’s market environment, what were the main challenges you faced in 2024 and what were the most important goals you achieved?

There were many challenges embraced, all with a lowest common denominator: crossing Italian and European borders. This entails the uncertainty of achieving the final result due to contextual issues. A greater incentive to always do better!

Which product lines are you working on and which do you intend to promote as a priority in the coming year?

We focus on plant control and continuous monitoring of production lines in relation to air pressure and energy consumption. Elements that focus on immediate control of the plant to improve consumption and performance.

What services or activities do you have planned for 2025 to engage and retain your customers?

Today, for us, research and development is aimed at reducing energy consumption as well as at the continuous improvement of production lines, whether they are manufactured by us or by third parties. This is because our systems can be easily integrated and implemented.

ESG (environmental, social and governance sustainability) criteria are increasingly at the centre of companies’ development strategies, what are the actions you have taken in this regard?

By oversizing even by one size the mechanical rotational components, which are subject to wear and tear, there is a reduction in maintenance and consequently in everything behind a part, from manufacture to shipping.

Criticality=opportunity: what are the critical issues you have encountered (or that your customers have shared with you) on which you have built valuable solutions for the industry?

Our added value is customisation. That is why the obstacle can be just around the corner. But this is the greatest incentive to achieve more and more important goals, which inevitably become an invaluable professional asset.

What role do exhibitions play in giving momentum to the development of new services and products?

Essential! Trade fairs are the meeting point between customers and suppliers. Talking about problems and solutions in a more ‘informal’ environment acts as a stimulus and a breeding ground for new developments and ideas.

THE PRODUCTS

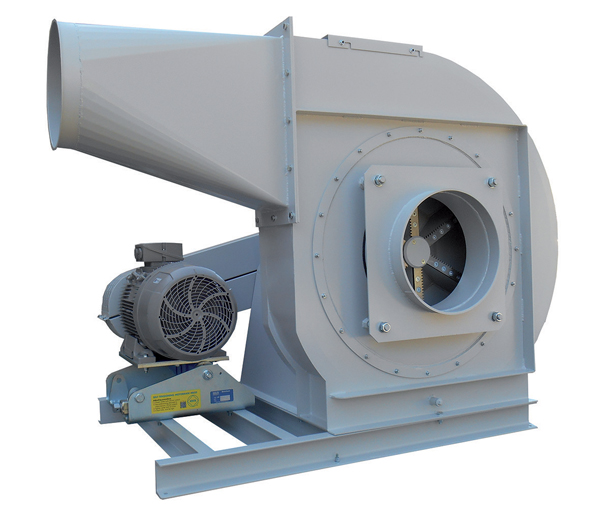

When we talk about New Aerodinamica we cannot fail to mention the milestone reached last year of its first forty years of company history. An important goal, the result of continuous innovation that has distinguished the company, a reference point on the national and international scene for the production of aspiration plants for waste and trimmings. To date, there are many countries in which the New Aerodinamica ‘flag’ has been placed. A key factor in this success has been the ability to create customised plants based on the needs of each customer, studying and realising, thanks to the skills and experience of the team from Bergamo, the best solution. As managing director Paolo Radaelli explains, “it all starts with the customised nozzles, the strong point of each realisation. Then comes the transition to our must-have, the chopper fan, complete with reinforced impeller, capable of reducing consumption and lowering noise. In this regard, I would like to highlight the latest version recently launched with incredible results”.

And when it comes to the chopper fan, an invention by New Aerodinamica, it is worth mentioning the possibility of choosing from nine sizes, a key element as it allows the customer to opt for the best performing configuration according to the specific need. From the chopper fan we then move on to the modular type conveying pipework with a collar and sealing gaskets. The latter feature allows all material and dust to be retained, leading to a reduction in pressure losses and thus a reduction in energy consumption. The process is then followed by the separator and the filter, both of which are important elements for the elimination of dust on discharge, useful for a cleaner indoor and outdoor environment. A product, the one created by New Aerodinamica, in line with the concept of sustainability, an objective that has always been pursued by the company, which over all these years has impressed for its attention to detail and the quality of the systems created, which are unique and absolutely high-performance.