GRAFIKONTROL SPA

Via Ludovico D’Aragona, 7

20132 Milano

Tel. +39 02 2100951

sales@grafikontrol.it

www.grafikontrol.it

Linkedin: www.linkedin.com/company/grafikontrol-spa/

MANAGEMENT

Paolo De Grandis, Sales & Marketing Director and Co-owner of Grafikontrol

Davide Filippi, President and Co-owner of Grafikontrol

BUSINESS SECTORS

Control & measuring equipment

PRODUCT RANGE

- Web Viewer & Statistical Print Inspection.

- 100% inspection for printing, large format digital presses and cold-seal.

- Instantaneous double-sided printing visualization with dual cameras.

- Automatic tracking, management and removal of defects.

- In-line color measurement and ink formulation correction.

- Color register control.

SALES NETWORK

Direct: agents throughout the national and international territory.

REPRESENTED BRANDS

- Techkon

THE INTERVIEW

Paolo De Grandis

Sales & Marketing Director and Co-owner

In a market context such as the current one, what were the main challenges you faced in 2024 and what were the most important objectives achieved?

The main challenge has been the increasing price competitiveness: the technologies we offer tend to become commodities with consequent downward pressure. However, the demand for high-performance solutions in the converting industry has allowed us to enter the digital printing market with unique and highly innovative inspection systems.

What product lines are you working on that you intend to promote as a priority over the next year?

In the coming year, we will focus on expanding the applications of our inspection systems, bringing them into new areas such as textiles, glass, batteries and printed circuit boards. At the same time, we are developing advanced solutions for in-line color control, an increasingly central issue in the printing world, where precision and visual quality make the difference.

What services or activities have you planned for 2025 to engage and gain customer loyalty?

For 2025, we aim to strengthen our relationship with our customers by offering 24/7 support in all the countries where we operate and preventive maintenance packages that will include software updates and enhancements to ensure the maximum performance of our systems.

ESG (environmental, social and governance sustainability) criteria are increasingly at the centre of companies’ development strategies, what are the actions you have taken in this regard?

ESG principles are integrated in our daily activities: we develop solutions that reduce waste in industrial processes, we promote a safe, inclusive and empowering work environment, and we adopt transparent and accountable governance. We believe that sustainability and innovation are key to sustainable growth. To confirm our environmental commitment, in 2024 we installed a photovoltaic system at Grafikontrol that produces more energy than is consumed.

Criticality=opportunity: what are the critical issues that you have found (or that your customers have shared with you) on which you have built valuable solutions for the sector?

Every criticality represents an opportunity for innovation for Grafikontrol. For example, the difficulty in tracking defects at various stages of production led us to develop EASYTRACKER, a system that by means of ink-jet micro-marking with variable codes allows the precise tracking of defects, associating them with the metreage of the printed reels for accurate and timely control and removal of rejects.

What role do exhibitions play in giving momentum to the development of new services and products?

Trade fairs concentrate the technological offerings of several companies in one place, giving customers the opportunity to compare solutions and innovations in a direct way. However, in recent years we have noticed a decline in attendance especially at events organised in Western countries, which is a sign of a change in the way the market interacts and is updated.

THE PRODUCTS

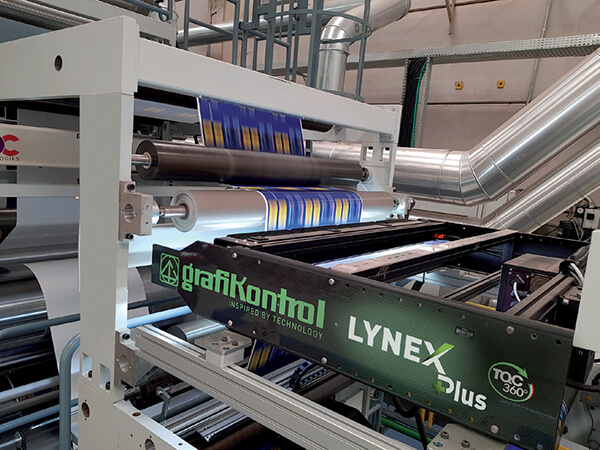

LYNEX PLUS: 100% inspection system for the print or surface control used a new-generation 8K cameras.

- MATRIX PLUS: web viewing system with a 9.6 Megapixel matrix camera mounted on a motorized traverse for continuous scanning of the entire web width.

- MATRIX C/S: dual camera system to allows simultaneous display of the front/back register.

- LYNEX PLUS: 100% inspection system for the print or surface control used a new-generation 8K cameras.

- LYNEX-S PLUS: 100% print inspection system dedicated to narrow web and neutral film including all the LYNEX PLUS features.

- LYNEX C/S: 100% inspection system specially designed to inspect cold-seal, varnish and coating.

- LYNEX EVOLUTION: 100% inspection system for digital machine of wide format. A dedicate software detects typical defects and analyses simultaneously the print and unique variable codes for each package at speed of up to 500 m/min.

- PARVIX: system equipped with a 1,3 Megapixel digital color camera that allows to display a 150x110mm field of view on a 24” multi-touch monitor.

- SPECTROVISION: system for in-line color measurement and ink formulation correction.

- PROGREX PLUS: a combination of the functions of MATRIX PLUS and LYNEX PLUS to form a complete tool, that helps the user with each print phase on rotogravure, flexo and offset presses.

- EASY-TRACKER: system for a full defect traceability and removal from printed rolls.

- CR50: register control for rotogravure and flexo presses (with additional downstream units) that ensures register stability among colors for the entire production and reduces waste.

EASY-TRACKER: system for a full defect traceability and removal