PROGROUP AG

Horstring, 12

76829 Landau (Germany)

Tel. +49 (0) 63 41 / 55 76-0

info@progroup.ag

www.progroup.ag

www.professionals-academy.de

Facebook: www.facebook.com/progroup.ag

Instagram: www.instagram.com/progroup.ag

Linkedin: www.linkedin.com/company/progroup-ag

Linkedin: www.linkedin.com/company/professionals-academy

MANAGEMENT

Maximilian Heindl, CEO

Dr. Volker Metz, CFO

Beate Flamm, CCO

Dr. MarcSesterhenn, COO

Vinzenz Heindl, Designated CSO of Progroup, current CEO Professionals Academy and JH Holding

BUSINESS SECTORS

Software and workflow – Substrate manufaturing for printing & converting

PRODUCT RANGE

High-quality containerboard and corrugated sheet board in a variety of profiles. Reliably delivered after a maximum of 48 hours after order placement.

SALES NETWORK

Two Sales Managers and a dedicated Sales Director for Italy effectively play an active role in the growth of Progroup in Italy.

REPRESENTED BRANDS

- Progroup AG

THE INTERVIEW

Vinzenz Heindl

Designated CSO of Progroup, current CEO Professionals Academy and JH Holding

Francesco Vidotto

Sales Director Western Europe

In today’s market environment, what were the main challenges you faced in 2024 and what were the most important goals you achieved?

Vinzenz: In the challenging global market environment of 2024, we encountered a variety of obstacles – including rising raw material costs and geopolitical uncertainties. Nevertheless, we reached several key strategic milestones. A particular highlight was the progress of our second plant in Italy, in Cessalto in Italy – at the heart of Europe’s biggest corrugated sheetboard market. The project is on track for completion in 2025 and marks a key step in our growth strategy.

What are the product lines you are working on and plan to promote as a priority in the coming year?

Francesco: In 2025, we will continue to focus on our Next Generation Products. With nextfibre®, nextboard® and nextbox®, we offer innovative, resource-efficient solutions that set benchmarks in sustainability and performance. These product lines are central to our strategy and will be key growth drivers in the coming year – addressing both customer needs and future market demands.

What services or activities do you have planned for 2025 to engage and retain your customers?

Francesco: In Summer 2025, we will launch corrugated board production at our new plant in Cessalto, Italy. The site features one of the most advanced corrugators on the market (3.35 m span), a fully automated vertical warehouse with 15,000 pallet spaces, and will produce both standard and high-performance board profiles. We’re not just supplying board – we’re delivering consistent quality, on-time logistics, and close partnership to support our customers’ growth. Most of the cardboard used will come from our own mills, ensuring superior fiber integrity and performance.

Vinzenz: Additional value is created by the Professionals Academy – like Progroup AG, a subsidiary of the JH Holding company – which supports customers with deep market insights, strategic guidance, sales development and succession planning. It empowers partners to grow sustainably and enhance their competitiveness in dynamic markets.

ESG (environmental, social and governance sustainability) criteria are increasingly at the center of companies’ development strategies, what actions have you put in place in this regard?

Vinzenz: Sustainability is key to our strategy. We aim to become climate neutral long-term. Our two waste-to-energy plants run entirely on refuse-derived fuel, converting paper production residues into energy – aligned with our zero-waste approach. In addition, we are socially engaged at all our sites and actively contribute to local communities, with a particular focus on supporting children and youth through education, sports, and cultural initiatives.

Critical issues = opportunities: what are the critical issues that you have encountered (or that your clients have shared with you) on which you have built valuable solutions for the industry?

Francesco: In Italy’s corrugated board sector, I’ve often seen two challenges: inconsistent paper quality and unreliable deliveries. Progroup solves both. Our advanced paper mills ensure uniform performance and color, while optimized internal processes guarantee punctual deliveries. At the same time, we focus on reducing our carbon footprint at every production and logistics stage.

WE MANUFACTURE THE FUTURE.

WITH CONTAINERBOARD AND CORRUGATED BOARD

Quality papers for the most demanding requirements

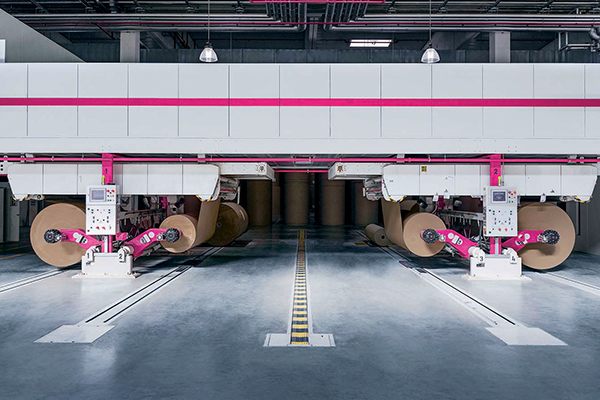

At three German sites, Progroup produces high-quality containerboard exclusively from recovered paper. These high-performance mills ensure the continuous and reliable supply of raw materials to our 13 corrugated sheet feeder plants across Europe.

Corrugated sheet board made to measure

At 13 European locations – including Drizzona and, from summer 2025, Cessalto in Italy – Progroup manufactures recyclable corrugated sheet board in single-wall, double-wall and triple-wall profiles. State-of-the-art machines ensure precision, flexibility and consistent quality – tailored to specific customer requirements.

Next Generation Products

Progroup develops patented Next Generation Products such as nextfibre® and nextboard®, combining lightweight design with high performance. These resource-saving products reduce raw material needs while improving strength and overall efficiency.

High-quality corrugated sheet board

With a broad portfolio including profiles like F, E, B, C and their double- and triple-wall variants, we are one of Europe’s market leaders in corrugated sheet board. Our nextboard® grades, made from nextfibre® containerboard, reflect a new generation of sustainable, high-performance corrugated solutions.

Smart services and digital integration

Our digital E-Box system simplifies ordering and tracking. Integrated logistics and our own fleet ensure efficient, reliable delivery and short lead times – with maximum transparency.

Sustainable by design

All sites are connected via the “One Mill” system – a real-time digital process and control platform that ensures standardised quality and maximum efficiency. We invest in future-ready technologies, from resource-saving paper machines to waste-to-energy power plants – reducing emissions and closing energy loops.