OMET SRL

Via Caduti Lecchesi a Fossoli, 22

23900 Lecco (LC)

Tel. +39 031 0741000

mkt@omet.it

www.printing.omet.com

Facebook: www.facebook.com/OMETSrl

Instagram: www.instagram.com/omet_srl

Linkedin: www.linkedin.com/showcase/ometprinting

Youtube: www.youtube.com/@OMETcompany

MANAGEMENT

Antonio Bartesaghi, CEO

Marco Calcagni, Sales & Marketing Director

BUSINESS SECTORS

Machines and equipment for printing & converting

PRODUCT RANGE

Narrow and medium web flexographic and combined machines for printing labels and flexible packaging.

THE INTERVIEW

Marco Calcagni

Sales & Marketing Director

In a market context such as the current one, what were the main challenges you faced in 2024 and what were the most important objectives achieved?

In 2024 we reached and exceeded our targets in terms of sales and installations, despite a slight slowdown in the Italian market due to a physiological contraction compared to 2023 when the market was driven by Industry 4.0 incentives. Other markets are seeing strong development, therefore the company has not suffered, recording a considerable growth compared to 2023. In particular, the collaboration with Durst is a major challenge we were able to meet, leading to the installation of more than 20 hybrid machines.

What product lines are you working on that you intend to promote as a priority over the next year?

KFlex, a line dedicated to the label printing market, and the XFlex X7, the line for printing flexible packaging and shrink sleeves, are among our most requested and most innovative printing solutions; there is also a lot of interest in the Varyflex V4 offset printing line, available with a width of up to 1,080 mm, because the flexible packaging market, not only that of labels, is becoming a priority for OMET.

What services or activities have you planned for 2025 to engage and gain customer loyalty?

We are investing in the offer of digital solutions, in particular in the OMET Digital Solutions product line, which includes the Sfera digital platform that allows to monitor all connected machines in real time, analysing all production data in order to take the best operational and production decisions.

ESG (environmental, social and governance sustainability) criteria are increasingly at the centre of companies’ development strategies, what are the actions you have taken in this regard?

The focus on energy saving has been the basis of every development on our machines for years, but that’s not all. Our machines allow for an important reduction in waste thanks to our new generation technologies and automation, helping our customers towards an increasingly sustainable production.

THE PRODUCTS

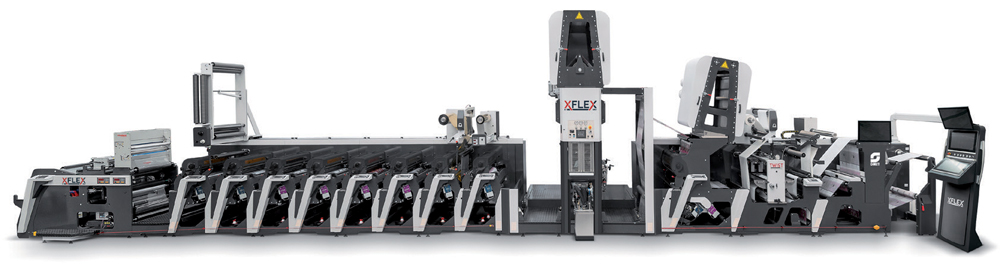

OMET continues to innovate in the printing sector with technologically advanced solutions, capable of responding to the needs of the label and packaging market. Among these, the KFlex and the XFlex X7 represent two of the most performing and versatile machines.

KFlex stands out for its modularity, allowing you to work with different materials and applications, from self-adhesive labels to shrink sleeves. Its Dual Servo independent flexo drawer, with latest generation servomotors, ensures precision in the print register. In addition, the optimised paper changeover reduces waste, while the touchpad interface centralises operations for a more intuitive management.

Thanks to the SWITCHsystem, the KFlex allows for the rapid replacement of printing and converting units, offering the possibility of integrating screen printing modules, hot foils, removable dies or digital print bars.

This flexibility makes it a cutting-edge solution, capable of quickly adapting to any production need.

The XFlex X7 was designed to address the need to meet the ever-rising trend in the market for high quality shrink sleeves and flexible packaging for small and medium runs, guaranteeing targeted efficiency in terms of quality, job change and production performance.

Thanks to fully servo motorized “Zero-Gear” flexo units and motorized printing pressures, the XFlex X7 guarantees high quality, eliminating problems of possible printing defects even at high speeds.

To meet the needs of the market, the X7 platform can be integrated with high-performance rotogravure printing units for front or reverse printing and finishing applications such as Soft Touch effects that add value to the finished product. The combination of these technologies allows to obtain high quality products and gives a substantial competitive advantage over the rest of the market.