Lugli Silverio chooses connection to build the company’s future. As a protagonist in the world of printing and paper manufacturing, today he leads the transition towards truly circular packaging: plants that transform paper waste into new compostable packaging within the same production chain.

We chose to join Converting Connection because we believe that innovation starts with relationships. This initiative is the meeting point between those who imagine (and make) the change and those who make it happen on a daily basis.

LUGLI SILVERIO

Via Morse, 2

41012 Carpi (Modena)

Tel. +39 059 8394203

info@luglisilverio.com

www.luglisilverio.com

MANAGEMENT

Silverio Lugli, Legal representative

BUSINESS SECTORS

Control & measuring equipment – Machines and equipment for printing & converting – Finishing and post-printing

PRODUCT RANGE

- Paper converting machinery.

- Screen printing lines.

- Die-cutting and laminating machines.

- Automatic platens.

- Forming and thermoforming machines.

- Folder-gluing machines.

- Machinery for security printing.

- Technical consultancy for printed matter.

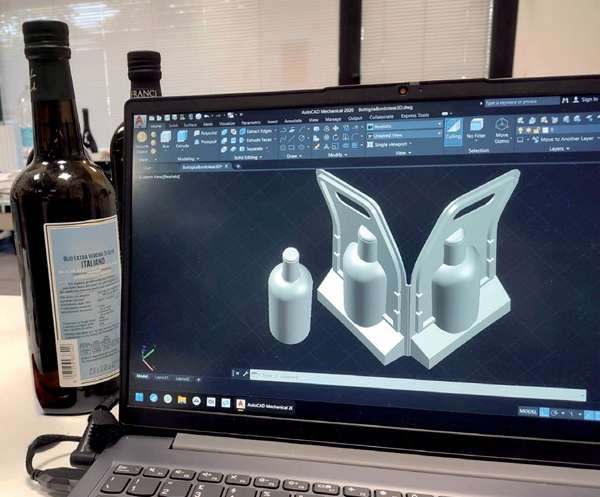

- 3D product design.

- Design of new production plants.

- Crushing and pneumatic handling of waste and trimmings.

- Machinery for the transformation

- of waste and trimmings.

- Industrial and food packaging.

- Pulp from recycled paper.

SALES NETWORK

Directly in Italy

THE INTERVIEW

Silverio Lugli

Legal representative

In a market context such as the current one, what were the main challenges you faced in 2024 and what were the most important objectives achieved?

In 2024 we completed our production flows by creating a circular economy that includes the pneumatic handling of waste and trimmings and the subsequent shredding for insertion in the pulper and processing this material into recyclable products

What product lines are you working on that you intend to promote as a priority over the next year?

Plants that transform paper waste into new compostable packaging within the same production chain.

What services or activities have you planned for 2025 to engage and gain customer loyalty?

Automation of the logistics of processed products, trimmings and waste, optimising the generated products.

ESG (environmental, social and governance sustainability) criteria are increasingly at the centre of companies’ development strategies, what are the actions you have taken in this regard?

We believe we are a reference point for optimizing all our customers’ resources.

Criticality=opportunity: what are the critical issues that you have found (or that your customers have shared with you) on which you have built valuable solutions for the sector?

Currently, the verticalisation of production leads to the reduction of small companies. Tax benefits help optimise the growth of large groups

What role do trade fairs play in giving impetus to the development of new services and products?

Trade fairs have a completely different role from the past, where the main objective was to increase production.

WHAT WE DO

Prototyping

Polpa Green Project