ERO GLUING SYSTEMS

Via Benedetto Castelli, 38-40-42

25010 Montirone (BS)

Tel. +39 030 2731503

info@ero-gluers.com

www.ero-gluers.com

Linkedin: www.linkedin.com/company/ero-gluers/

MANAGEMENT

Francesca Notari, General Manager

BUSINESS SECTORS

Control & measuring equipment – Finishing and post-printing

PRODUCT RANGE

ERO-DL Intelligent Glue Inspection System

THE INTERVIEW

Francesca Notari

General Manager

How is ERO innovating the market through AI?

We aim to bring our customers’ ideas to life: smart, reliable systems that reduce setup times while saving on costs. What once seemed impossible became a challenge we willingly embraced. Fifteen years ago, ERO took a bold step by betting on artificial vision to inspect the position of glue patterns. At the time, we believed that if a system could identify glue as accurately as the human eye, it would provide significant value. However, this was no easy task. The technology available then, combined with the complexity of programming numerous commands, resulted in systems that lacked true intelligence. Operators had to invest considerable time setting up the system and have specialized knowledge to navigate its intricacies and minimize false alarms.

Today, with advancements in hardware and algorithms (led by the power of AI) we feel a strong responsibility to harness these opportunities to simplify our customers’ workflows and provide more cost-effective solutions.

The new ERO inspection system has been trained with thousands of images of both good and faulty glue patterns. Through this training, it has become highly independent, capable of recognizing glue regardless of artwork, crease lines, edges, or any other objects captured by the camera. This powerful tool is the breakthrough we have been pursuing for years: a system that detects glue with the precision and experience of an operator’s eye.

Why is the ERO-DL solution unique compared to others in the market?

The ERO-DL is the first glue inspection system in paper converting powered by AI technology, making it truly unique. With this system, we aim to push the boundaries of the state of the art. We aim to advance the state of the art with this system, and to highlight this effort we have submitted a patent for this idea.

What new developments or initiatives is ERO planning in the near future?

It enables us to implement new tasks and access data with ease. We plan to expand this technology into areas like corrugated glue inspection and take on further tasks in the folding carton market, including gluing and sensor inspections. Our mission remains the same: bringing our customers’ ideas to life!

Artificial intelligence applied to folding carton manufacturing

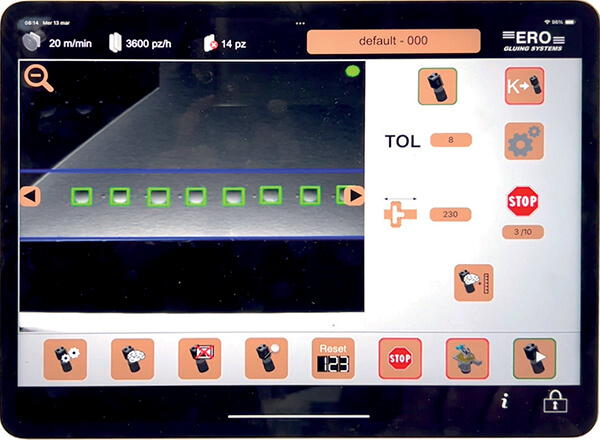

The ERO-DL technology is controlled via an iPad which seamlessly integrates cold glue applicator control and model inspection into a single interface.

ERO Gluing Systems is at the forefront of integrating the benefits of Artificial Intelligence into the gluing sector with ERO-DL, the cold glue inspection technology.

After over a year of research, ERO’s Engineering Department has perfected the ERO-DL cold glue control technology, whose advantages surpass those of a traditional inspection system. The ERO-DL adhesive inspection system incorporates cutting-edge deep learning technology, enabling automatic parameter setup for every processed carton. Trained with an extensive database of glue pattern images, the AI eliminates the need for manual presetting or adjustment by operators, thereby streamlining the production process, even for new orders.

“We are excited about the launch of the ERO-DL system. We are confident that it will greatly assist our customers by shortening pattern setup times and offering the smartest way to apply glue patterns”

All of this results in reduced machine downtime for batch changes.

Control of the ERO-DL technology is done through an iPad that seamlessly integrates the control of cold glue applicators and pattern inspection into a single device. This innovative system not only enables remote connectivity for controlling and checking parameters from any location but also enhances performance through customized remote training on special formats.

The ERO-DL camera operates with the precision of a human eye: it can detect adhesive points and beads on any surface. This includes delicate substrates such as aluminum or other reflective surfaces, which have posed a real challenge until now. The use of adhesives with UV additives is also no longer necessary, making it the ideal system for the food industry.

The system comes standard with the ERO-GTE 13 applicator that can apply glue dots to get important glue savings, although it is compatible with any system on the market.