BST ELTROMAT ITALIA SRL

Via Angelo Volonterio, 36 A

21047 Saronno (VA)

Tel. +39 02 96 199701

info.italia@bst.group

www.bst.elexis.group/it

Linkedin: www.linkedin.com/company/bst-eltromat-italia-s.r.l./

Instagram: www.instagram.com/we_are_elexis/

YouTube: www.youtube.com/@BSTInternationalGmbHBielefeld

MANAGEMENT

Paolo Tamburrini, Managing Director

BUSINESS SECTORS

Software and workflow – Control & measuring equipment

PRODUCT RANGE

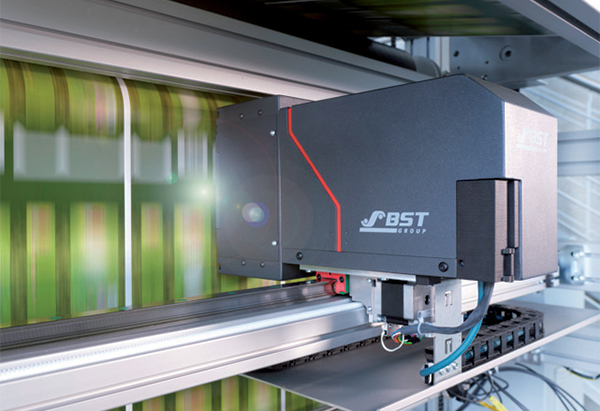

The BST Group is a leading manufacturer of quality control systems for the printing and packaging industry in web-fed processes. The broad product portfolio includes web guiding systems, print monitoring and visualization, print or surface inspection of neutral materials, registration controls, color measurement and workflow solutions from prepress to finishing.

RAPRESENTED BRANDS

- BST GmbH

- Nyquist Systems

THE INTERVIEW

Paolo Tamburrini

Managing Director

In a market context such as the current one, what were the main challenges you faced in 2024 and what were the most important objectives achieved?

In recent years, BST, like everyone, has faced a market environment characterized by rapid changes and unexpected challenges, such as fluctuating raw material costs and supply chain management. Despite these particular conditions, the company has managed to adapt and continue to invest by extending its product portfolio, introducing new technological solutions for process control and, thanks to the inauguration of the Sesto Fiorentino production plant, the iPQ Surface surface inspection system.

What product lines are you working on that you intend to promote as a priority over the next year?

Despite consolidating its leading position in providing innovative solutions for converting, BST is very attentive to the emerging needs of its customers and develops solutions that allow them to address their main critical issues, in line with the #FORYOU campaign!

What services or activities have you planned for 2025 to engage and gain customer loyalty?

Our R&D is always looking for innovative technological solutions, such as the optimization of algorithms with AI sup-port, digitized and interconnected solutions that allow waste reduction, process optimization, operational efficiency, data tracking and the possibility of integration with third-party application systems.

ESG (environmental, social and governance sustainability) criteria are increasingly at the centre of companies’ development strategies, what are the actions you have taken in this regard?

In accordance with the growing expectations in terms of sustainability, BST has implemented numerous actions in the ESG field, adopting various interventions such as: more sustainable production practices, reducing the environmental impact of processes and products, promoting easily integrated modular technological solutions; facilitating inclusion policies, creating a work environment that enhances everyone’s skills; strengthening transparency in our operations and in the relationship with our stakeholders, improving audit and control processes.

I PRODOTTI

BST offers a range of products for industrial automation and quality assurance in rotary web processes. Here are the main products:

- Web guiding – ECOGuide, SMARTGuide, COMPACTGuide, DF, SF, FRAME GUIDE and Winder Package: precisely and reliably monitor and correct the position of the web in different production processes.

- Colour register control – AR4400, Twin Star and Regi Star 20: use fibre-optic scanning heads or CCD cameras to control and correct colour register, insetter and finishing, by reading marks printed in Web-Web or Web-Cylinder mode.

- Video print monitoring – PowerScope 5000, ProView, iPQ View: enable simple and efficient video inspection of print, even at high speeds.

- 100% print inspection – Tubescan Digital Strobe, Tubescan XL, iPQ Check: 100% real time inspection systems of print defects to ensure high quality products, reduced waste and tracking.

- Colour measurement – iPQ Spectral: systems for in-line spectrophotometric measurement and analysis to ensure prescribed colour standards.

- 100% Surface Inspection – iPQ Surface (Defects, Coating, Cold Seal, Energy): system for inspecting defects on un-printed material, coatings and finishes to ensure quality and integrity.

- Workflow management – SMARTData: enables the collection and management of data in order to optimise produc-tion processes from prepress to finishing.

- Colour management – FSS15: optimally adjusts electronic colour dosing settings via remote control of offset press-es.

- Automation Solutions: provide efficient process automation solutions for both machine manufacturers and end users.

The FORYOU campaign shows how the presented innovations can make everyday production easier and more sustainable.

Monitoring system installed on printing machine.