#Inciflex, #Oxea, #Rossini, #Sun Chemical, #Uteco, #Windmöller & Hölscher have turned to Converting Magazine to disseminate technical and marketing content in Italy and abroad, to do education and branding, to advertise products and inform about TOP↑ corporate events of the year. Here is a preview of the articles they published in the first issue of the year, online at www.convertingmagazine.it and soon coming to your desktops.

A renewed issue featuring richer content is on its way to our readers’ desktops. One of the distinctive sections of our magazine – the “Special” focused each issue on an aspect of printing and converting – becomes an enquiry where the protagonists speak first-hand.

Thanks to the collaboration with experts working hands on, on a daily basis, a new section has been created which aims to analyse the actual modus operandi of printers, both flexo and beyond, to highlight the implications of the methodologies and technologies adopted. The contents regarding sustainability multiply and reflect on the logo, making it even greener, as (we hope) the whole world will become.

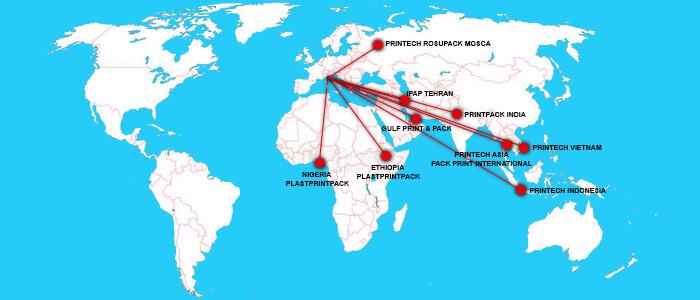

A renewal that also features the magazine’s “Power Sponsors”, i.e. those companies that have adopted this particular communication formula integrated into the Converting editorial platform. It is a formula that enables the full exploitation of all the channels available throughout the year: in addition to Converting magazine, this also includes our website, our national and international newsletters, the social networks of our publishing house, and the distribution of the magazine at a series of selected national and international trade fairs. A way to increase the effectiveness of messages, thanks to the maximum visibility gained by Power Sponsors in all media. A way to maintain constant and direct contact with readers and the market, this too via the contribution of our editorial staff.

Converting 2020 Power Sponsors are partly “old” traveling companions and partly new entries. Six companies (to date) that represent recognized excellences in their respective areas of expertise and cover all segments of the supply chain, from prepress to printing, going by way of the consumables that make the difference. You will hear about it all year round – a special year, due to the importance of the sector events (drupa obviously, yet much more besides) – but also due to the economic and technological challenges that everyone is inevitably called upon to face.

We are proud to have them as partners and to introduce them to you through the latest articles in which they feature.

INCIFLEX SRL

Inciflex Srl, which has put its faith in us since the launch of the Power Sponsor formula, is one of the main Italian prepress services. Headquartered in Fisciano (SA), with subsidiaries in Milan and Algiers, it represents one of the jewels of Italian entrepreneurship and one of the poles of the huge southern Italian converting district. It came into being as a prepress specialist aimed at producing flexographic systems, subsequently integrated with rotogravure lines, and today – supported by a strong propensity for innovation and experimentation – it can offer itself as a unique and complete partner, equipped with state-of-the-art skills and technologies, both in gravure and flexo printing as well as for corrugated cardboard. With the help of first-rate technological partners, the company can boast a series of firsts, launching its Ultra Led Technology at the last Flexo Day in Bologna, featuring a new and innovative screening technology for flexographic printing that equals, and in part also exceeds, the quality of gravure highlight printing. The complete article presenting can be read online and in Converting 1/2020.

OXEA

Oxea is a large chemical concern with offices and plants in North America, Europe and the Far East. Born in March 2007 from a buyout operation in oxo derivatives and oxo intermediaries of two other international companies, since December 2013 it has been part of the Oman Oil Company (OOC) group. In Oxea two strong distinctive characteristics are perceived. Firstly, the ability to expand its range of products to meet all market needs, which has given rise to more than 70 oxo-chemicals for the various target applications including inks, lacquers and coatings for printing but also, among the derivatives, phthalate-free plasticizers, lubricants and coatings. The second characteristic concerns the sustainability of the Oxea, offer both in economic and environmental terms, to respond to the ever growing importance in being able to offer environmentally friendly solutions. See our article on Oxea’s Propyl solvent published in Converting 1/2020 for further details.

ROSSINI SPA

Rossini SpA has been a sponsor of Converting since the first issues of the magazine. It is a historical reality in our sector: a pioneer of national industrialization (Rossini came into being on the outskirts of Milan as a shop for saddles and horse harnesses) has gradually been able to grow internationally becoming an ambassador of Made in Italy. Today Rossini is one of the largest, reputed and innovative worldwide producers of rollers and die-carrying sleeves for gravure, flexo and offset printing, as well as for lamination and coating, that are flanked by the plants and machinery of the Rossini Equipment Division for treatment and maintenance of the rollers. Added to that, the company operates worldwide as partner of the large OEMs to which it supplies components and products and, aboveall, development consultancy. Not to mention that at conferences and in the economic press the company is cited as a business management model. Among the many possible testimonials, we propose the article published in Converting 1/2020, which can also be read online.

SUN CHEMICAL GROUP SPA

The Italian branch of the ink giant headed by DIC Corporation has renewed its faith in our magazine. Last year we dedicated many special feature articles with a technical slant to them – we cite the in-depth studies dedicated to adhesives, but also stories of surprising and high-value applications, such as the original “ink” created for the Eurostampa label of Barolo Balena, their support for the packaging culture as a whole, their commitment to sustainability and safety, the results of large investments in R&D and the opportunities created by comparisons made between the Research Centers and the Laboratories of the Sun Chemical network all over the world … And undertakings which everyone talks about, like the annual event dedicated to top ranking converters and printers, which offers an unprecedented mix of service, updating and social life, representing a milestone in public relations. In the first issue of the year we talked about their new Chemical Laboratory and the services it offers to customers.

UTECO CONVERTING MACHINERY

Uteco Converting Machinery is one of the great OEMs in the printing and converting sector for flexible packaging, but also one of the “pocket multinationals” which represent an all-Italian business model – today under the umbrella of the private equity fund NB Renaissance, which has invested in its further development. Uteco produces in Italy and North America and, to serve a growing demand, continues to invest in the expansion of its plants. An open minded management effectively controls both the market and sector institutions but, above all, invests in technological innovation. The results of the large investments in R&D that affect all technologies and business areas, and the close collaboration both with the technological partners (Kodak in the digital world, i.e., or Basf, Flint and Saueressig for the brand new water based gravure and flexo inks…) and with the converters and brand owners, can be seen at fairs and dedicated events. We also talked about the same as an industry 4.0 model in the first issue of the year of Converting. Here is the link to the article.

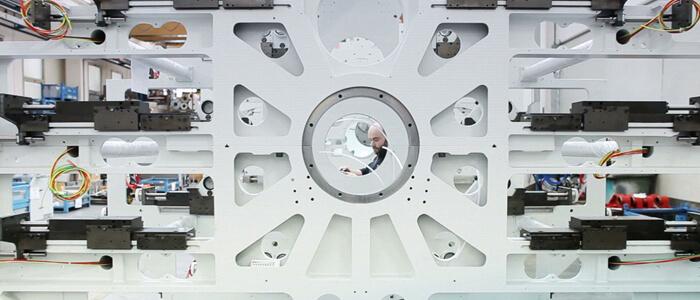

WINDMÖLLER & HÖLSCHER

W&H is the very latest company to have joined Converting’s Power Sponsorship project. The large German OEM, with an Italian branch in Lodi and operations worldwide, is one of the leading global manufacturers of printing, converting and extrusion lines. In the printing area W&H stands as a benchmark in flexo and gravure technologies, and in the autumn of 2018 it announced its entry into digital with its first single-pass machine for flexible packaging. For converting, the Lengerich based manufacturer’s catalogue aboveall offers equipment for producing industrial paper bags, together with block and flat bottomed bags and shoppers these too in paper. In the extrusion field W&H produces lines for blown and cast film, fabric, stretching and winders. In Italy W&H plays a leading role, with a strong staff of Italian technicians and more than 200 installed machines (the figure is constantly increasing). A recent case? Here it is.