The Italian Rotogravure Group of Acimga is working on an ISO standard draft dedicated to rotogravure packaging printing. The objectives, very concrete, are of a technical, managerial and “international politics” nature, and present significant advantages. Interview with the coordinator, Carlo Carnelli.

The ISO 12647 family of graphic arts is divided into a series of documents that define the standards, shared internationally, on the “good practices” in sheet and reel-fed offset, rotogravure editorial, screen-, flexo and digital printing, etc. With an important void: there is no ISO covering rotogravure packaging printing which, as is known, requires the implementation of specific flows and tools, different from other applications.

The Italian Gravure Group of Acimga has decided to fill the gap and submit the proposal to the competent working table, thus applying themselves to setting things right in a field in which the Italian industry stands out par excellence on a global level. What this means and in concrete terms, what ithe purpose of the new standard is explained by Carlo Carnelli of ColorConsulting, since 2008 nominated by UNI ISO TC130 expert, national coordinator of the UNI U50010902 “Graphic Technology” subcommittee and from the end of 2019 head of the Technical-Regulatory Committee of Acimga. An assignment accepted with enthusiasm: “In the roto group and more generally in Acimga I found a rare level of participation and responsibility. Together with the concreteness of objectives and projects, it represents a winning premise for working effectively and the first results clearly demonstrate this: the Guide to rotogravure printing, published in Italian and English in a few months, the “just in time” start of work for the ISO standard on rotogravure for packaging and other unscheduled interventions, which required competence and immediacy of response. Thus structured, we can make the voice of Italian manufacturers heard internationally, defending a know-how and an industry that deserve attention and recognition”.

Why an ISO standard for rotogravure packaging printing?

The ISO standards define “good practices” shared within the supply chain at an international level, concerning the work flow in the various industries: from communication to process to controls. Therefore, they also define the reference quality standards and represent a valuable document in case of disputes between partners. They are very useful, for example, when supplier and customer – in our case printer and brand owner – do not have all the skills necessary to translate the characteristics of the work to be performed into intersubjective data: color, rulings, tolerances … which they often do not understand.

But not only that: sharing a procedure greatly simplifies the work. Certainly for the printer, who can set up a single flow accepted by the great part of the customers, but also for the machine manufacturer who, during testing, can rely on a standard procedure.

What is the relationship between ISO standards and quality certifications?

Ideally there should be a direct and univocal relationship: the certifying body works to ascertain the correspondence of products, services etc. to ISO standards and the company obtains valuable information from it to improve internal processes, achieving greater efficiency and all the necessary compliance to obtain/renew certification. Unfortunately, this is not always the case. Especially in Italy (but not only), companies have underestimated the real importance of ISO certification and instead of striving to achieve the quality and efficiency levels that derive from it, they often see it only as a “stamp” to exhibit – a bit like a purchased degree.

But it’s a serious mistake. The certification serves to guide the reform of the procedures and production of companies in view of a concrete and better level of quality and efficiency and, precisely for this reason, it also becomes an international marketing tool.

We know that “political” games are also played at the ISO and UNI tables, in support of the one or the other national lobby. But what does it mean in essence?

I make a simple hypothesis to clarify: if a country builds machines that are not able to achieve the performance of the Italian ones, their representatives will work in ISO to modify the quality standards – in this case downwards. Here, “political” games therefore have very concrete objectives of protecting the market.

Other times, however (but the two are actually connected), “branding” is done: the negotiations aim to confirm the leadership of a nation in a given technology, attesting to its prestige. This is the case of our country in the field of rotogravure, where it is more than legitimate for the Italian gravure group to lead an ISO standard: together with the Germans and the Swiss (if we want to consider the corporate headquarters of Bobst), our manufacturers are in fact the world leaders, and they are the ones who define the quality standards. Provided that Germans and Swiss do not aspire to the same role …

We were ready for the Berlin meeting, which was canceled due to Covid-19, with defined title, purpose and index, and with the necessary support of a number of nations. Hence let’s get going again!!

What is the timeframe for publication?

Since each passage and amendment of the text must be approved by all the participants at the table, the timing can vary from 12 to 24 or even 36 months. Since rotogravure is a consolidated technology and, at least in the West, with a relatively limited number of actors, we can reasonably aim for 24 months. Unless, as I mentioned, problems raised by other countries, or even by representative institutions interested in attesting their influence in this sector. One thing is certain: the cohesion and speed of response of Acimga’s rotogravure group are a great advantage.

In the ISO field, have you carried out other works related to rotogravure?

Yeah. In the past months another working group (WG13) of ISO TC130 was publishing a technical specification (ISO/TS 19303-1 Graphic Technology – Guidelines for Schema Writers – Part 1: Packaging printing) with its annexes for each printing process, but the part concerning rotogravure was little more than mentioned. Having just formed the rotogravure regulatory group, we immediately asked the document editor for an extension of time, who gave us one month to draft a suitable text: we drafted it in record time and due care, so much so that it was accepted by all and now forms part of the standard.

For Acimga you also follow other tables and other problems: what’s in the offing?

There is a lot of meat on the fire. In addition to working groups such as the WG3, where we talk about processes and controls, we are also in the Work Group 13 committed to rewriting the rules that certification bodies must adopt to prevent companies with the same ISO quality certificate from actually working in a different way, as had happened for example in offset. We are also working on the WG11 on the environmental impact of graphic arts, where we are starting to draft a specific standard on packaging. Presiding over these tables in a structured way, on all technologies and themes, and with the full force of an entire industry is essential.

And the machinery legislation?

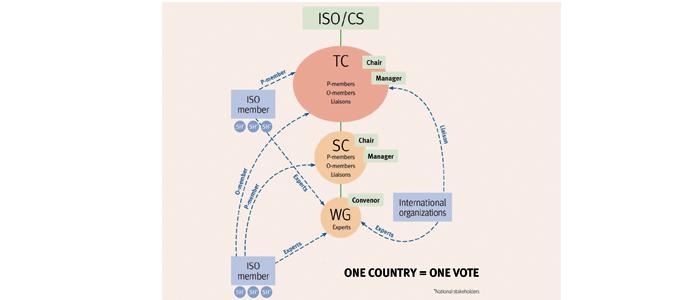

It is essential: for Acimga I will continue to oversee the work, with the support of the appropriate experts to suit each case, because, personally, I’m not a security expert. With one conviction: the work on standards, whatever they may be, must be done first of all at national level because those who vote, in the end are the nations; moreover, with a strong national impact we can bring benefits to the whole supply chain