How printing plate-level identification and scanning unlock operational excellence.

Set foot in a modern plate room and you’ll find an environment under pressure. Demands on packaging and label printers are multiplying – a single food product may require dozens of plate variations for size, language, and configuration. Across an entire portfolio, archives can easily swell to 40,000–80,000 tools.

Yet despite this complexity, many plate rooms still rely on inefficient manual processes to track and retrieve plates. The result: higher downtime, reduced throughput, and risks to customer trust. In this context, the case for plates with a “memory” – unique identification and scanning – is stronger than ever.

The plate room problem

Consider an operator tasked with retrieving plates for a run. Labels are often handwritten or generic; logs may be paper-based or spread across spreadsheets. Finding the right plates can take minutes – time that multiplies across dozens of daily changeovers, draining productivity and creating opportunities for error. These challenges intensify as presses run shorter, more frequent jobs. Manual systems simply cannot keep pace.

What if plates could remember?

Advances in workflow technology now make this possible. By giving each plate a machine-readable identifier such as a barcode or data matrix, printers can turn every tool into a connected asset. Solutions like Track&Trace4Tools and Scan4Tools from The Grey Elephant (TGE) deliver this capability. Track&Trace4Tools records every plate, tracking movements, usage, and maintenance events. Meanwhile Scan4Tools provides the hands-on interface, allowing operators to scan plates in and out of storage, onto presses, or through cleaning with handheld or integrated devices. The impact is immediate: retrieval drops from minutes to seconds. Operators scan a job ticket, and the system highlights exact plate locations, flagging mismatches instantly. Maintenance teams can view a plate’s entire history, supporting predictive care and extending tool life.

Operational excellence

The benefits ripple across production. With plates tracked and verified, error rates fall, waste is reduced, and customer satisfaction rises. Efficiency improves as skilled staff spend less time on manual searches and more on higher-value tasks. Faster, more reliable changeovers support the industry shift toward shorter runs and frequent switches. Traceability also strengthens compliance. In the event of a recall, companies can instantly see which plates were used, when, and by whom – detail that reassures both regulators and brand owners.

More than the sum of their parts

The real power lies in integration. Track&Trace4Tools forms a closed-loop system that logs every plate interaction. Linked with ERP and production management platforms, they extend visibility end-to-end. This is amplified by Brain4Tools, the orchestration engine that unites plate data with prepress and ERP systems.

Brain4Tools memorises and automates tool data. Artwork files are compared automatically for commonalities; jobs can be scheduled with efficiency in mind. The platform recalls if similar plates already exist, avoiding duplication and maximising value from each asset. By centralising all data, Brain4Tools provides real-time visibility – giving managers clear insight into plate availability, location, and readiness.

Together, these systems create not just plates with memory, but a plate room where that memory drives continuous improvement and competitive advantage.

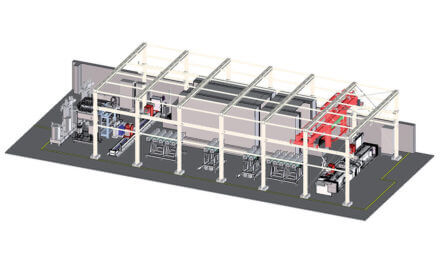

Towards a smart plate room

As printing demands accelerate, manual processes are increasingly unsustainable. Plate-level identification and scanning, powered by TGE’s integrated solutions, offer the efficiency needed to thrive.

By effectively giving plates a memory, companies can make their plate rooms more agile, accurate, and resilient. The question is no longer if this functionality is needed, but how quickly it can be adopted. The tools are ready, the benefits are proven, and the time to act is now.

For more information, visit: www.the-grey-elephant.com