Italgrafica Sistemi is the first company in the world to invest in the brand new Omet XJet, developed in collaboration with Durst and just launched on the market, defending the reputation for open-mindedness and creativity of approach to the market gained in the field by Italian enterprises.

The Omet XJet is a hybrid machine that promises high levels of productivity in all types of print runs, combining the advantages of flexographic and digital in one solution. Italgrafica Sistemi, based in Castelgomberto (VI) and specialized in printing and production of adhesive labels, chose it primarily for its compatibility with inline multiprocessing configurations, making the finished product in just one phase.

All the specials works in a single machine

The Veneto company has a turnover of 11 million euro with 50 employees, and works on two shifts. In its works 18 printing lines are already up and running and it is expected that the new hybrid (provided through LIRMAprint, partner of Durst and Omet for distribution) will replace two of the preceding flexo lines, in a drive to adopt suitable technologies to respond to the growing need for customization, reducing print runs down to a single pass. The introduction of the new machine will open the door to new opportunities for applying cold foil, reverse and adhesive label printing, as well as coating and die-cutting.

Economic and strategic advantages

As explained by Francesco Niorettini, General Manager of Italgrafica systems, the total cost of ownership and customer benefits played a crucial role in closing the purchase: «This investment opens the door to a new world of opportunity» – he said. «It enables us to offer more choices to the market and to produce many more different types of labels for any kind of order. Thanks to the incorporation of the Durst Tau system, we will be able to expand our portfolio by combining all the technologies together. Another aspect of major importance is to maintain the same high level and definition produced with flexo and offset printing, and the Omet and Durst hybrid solution allows us to achieve just that. Other factors that convinced us to invest were a 50% speed increase, cost containment for assistance, supplies and consumables and the fact that both Durst and Omet enjoy an excellent reputation on the market».

We have seen it at Print4All

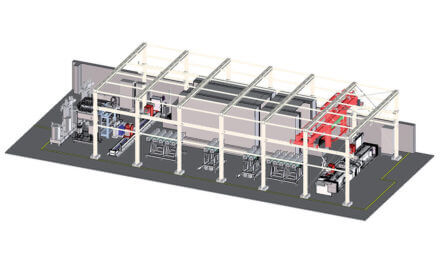

The Omet XJet – that has been present at the Omet stand at Print4All 2018 – combines the Durst Tau inkjet RSC printing unit and the Omet X 6 flexo units converting modules, including the exclusive Monotwin Cut, ideal for printing Pantone colors and full backgrounds, not to mention the finishing and conversion modules. Omet Xjet, says the manufacturer, is the only machine with inline multi-process design, which allows for the production of high value added labels in a single pass. Moreover, thanks to the digital module, jobs that normally would not be cost effective if printed on a machine with much higher productivity become feasible, with a guarantee of maximum quality.