The industry has got bogged down, the world has stopped and drupa has been postponed for a year: Enough to undermine any marketing strategy, and in fact product communication has slowed in recent weeks. But there are those who take advantage of the extra time available to dedicate themselves to marketing, and consider that the period is favorable for proposing new products.

[su_expand more_text=” Keep reading ” less_text=”Hide” height=”100″ link_color=”#fd0014″] Like Saldoflex, which in collaboration with Bosch Rexroth has developed and industrialized a large format CI flexo machine with innovative and highly interesting features. It was to have been launched at drupa 2020 and will be launched at drupa 2021, but in the meantime the dynamic company from Varese is introducing it to users.

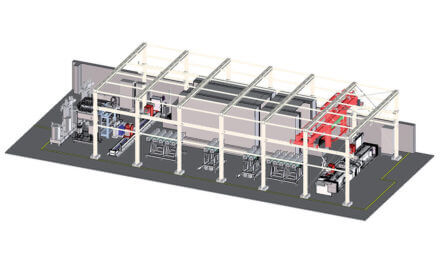

From the technological synergy between Saldoflex and Bosch Rexroth comes an innovative proposal. It is called LEAF-S8 and is presented as the most compact central drum machine for large format printing on the market.

Saldoflex – globally proven in the fields of automatic traysealers for plastic films and flexo stack-type printing machines – with the new LEAF-S8 makes its entry into the high-end packaging and converting market. Thanks to its solid positioning in printing and industrial packaging, and its collaboration with the automation giant, the manufacturer from Varese has developed a machine that is able to compete at the highest levels in the field of quality packaging. Here are some anticipations.

Brain and heart in automation

Starting with the “brain” of the machine, driven by the IndraMotion MLC75 control systems, the innovative LEAF-S8 concept has taken shape thanks to Bosch Rexroth Automation solutions, including large-format MBT torque motors, MS2N motors, IndraDrive CS Advanced drives and EFC 5610 drives.

Based on Artificial Intelligence & Machine Learning concepts, LEAF-S8 provides users with a decisive reduction in production waste. Among other things, the advanced level of User Experience (with customizable HMI and the possibility to control all parameters through touch screens located in different points of the machine) and the innovations resulting from FEM and CFD analysis conducted by Saldoflex R&D.

[/su_expand]

[su_expand more_text=” Keep reading ” less_text=”Hide” height=”100″ link_color=”#fd0014″] And like BFT Flexo – young and dynamic Piedmontese company belonging to the BFT group, specialized in inking and washing systems for flexographic printing – which in recent weeks presents, on all communication and promotion channels, a new inking and washing system specific for corrugated cardboard. Strongly automated, it has superior features and performance.

It’s called GT-Corr and is specifically developed for the world of corrugated cardboard to optimize process performance and maximize savings. These objectives are achieved thanks to the implementation of some special functions, which are activated with the utmost simplicity from the touch screen.

Three times smart, even on dated machines GT-Corr is equipped with a Siemens PLC and is able to regulate the inking speed digitally, recover the ink from both the delivery and return lines and wash the system with unprecedented efficiency.

Furthermore, GT-Corr enables the monitoring of the pressure of the doctor blade chamber. Through the screen, the operator not only starts the pumps but independently places the anilox in contact with the doctor blade chamber, keeping track of the pressure used. This enables the life of the doctor chamber blades to be monitored and tracked.

Furthermore, the new system enables the optimization of the color change, making it quick and autonomous even on dated machines without electronics on board.

GT-Corr is available in the three versions IR (the basic one) and IRW and IRWT. The latter differ from the IR respectively for the management of the discharge (IRW) and for the possibility of controlling the ink temperature (IRWT).

[/su_expand]