The corrugated packaging market and the changes in demand dynamics in light of the current difficulties and the potential of digital printing.

Packaging is a critical enabler for the everyday lives of consumers across the globe. During the peak of the pandemic, packaging converters saw an increased demand for high graphics corrugated packaging across a wide range of applications, especially on the e-commerce front. In parallel, supply chain challenges negatively impacted the ability to capitalize on this growth. Rising costs of consumables, paper, energy, and distribution had, and still have, a negative impact on converters’ bottom line.

As economic indicators point strongly to a downturn in the economy, consumer spending behaviors are changing. Rising interest rates and inflation pressures lead to uncertainty which reduces overall consumer spending. This can very quickly lead to excess brand and retail inventories, which may eventually expire or become obsolete, tie up cash flow, and occupy warehouse space. In addition, economic pressures lead consumers to switch brands more often, searching for cost-effective alternatives for their families. This in turn challenges brands’ ability to forecast accurately, which often results in either shortages or excess inventories.

As a result, demand for packaging is also impacted. Agile brands that respond fast to changing consumer demands will build resilience and prosper. Digital print for packaging delivers many substantial benefits that converters can offer their brands to address this volatility in demand.

Say yes to every job

Digital print is agile and flexible – it enables innovative campaigns, versioning, and personalization to boost engagement. Converters can offer brands unique campaigns with low project entry costs. With solely analog capabilities, converters need to impose MOQs, assume the burden of plate making for short runs, or outsource the short run jobs. Digital print removes these constraints. Converters can print small quantities, with multiple graphic changes during the life cycle of a product with minimal effort. Fighting for consumer engagement and brand preference is easy with attractive graphics and frequently updated designs.

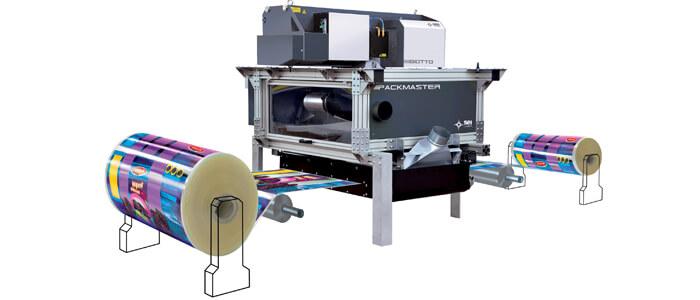

Contrary to the saying “don’t judge the book by its cover”, with digital packaging produced by HP PageWide corrugated solutions, consumers are welcome to judge the goods by the quality of the packaging. With HP technology, converters are producing offset print quality without the headache of the offset process.

Sustainability is not just a buzz word

Sustainability has become a game-changer for businesses of every type. Millennials and Gen-Zers prefer to engage with environmentally conscious brands that offer a sustainable impact and are also willing to pay more for sustainable products and environmentally friendly packaging.

Corrugated material is circular by nature as a paper product: on average new corrugated packaging is made from 89% recycled materials, and it’s 100% recyclable and biodegradable. When used as raw material for high graphics packaging, there’s an opportunity to maintain this high sustainable profile, assuming the additional raw materials and processes are sustainable as well.

When choosing the HP True Water-Based ink, converters can provide their brands with packaging that is harmonious to standard recycling processes without additional steps like de-inking.

However, having a highly sustainable profile is not just about recycling. It is also about generating less waste, saving on water, and providing a healthy environment for your employees. Digital technologies allow converters to print what they need when they need it – eliminating the need for warehousing and saving paper with quick setup and minimal make-ready. Digital technologies also save water. Specifically, with the HP Thermal Inkjet technology, printheads cleaning is an automated process that uses a dump cloth, unlike the large amounts of water that are used for cleaning up analog ink stations between jobs. Choosing HP PageWide technology and HP True Water-Based inks also benefit the operators with a clean, odor-free, and safe work environment with no hazardous air pollutants and low volatile organic compounds.

Build resilience against attrition

COVID introduced the world to new ways of employment. Attracting talent to a manufacturing career was a problem pre-pandemic and is now an even-greater challenge. Corrugated converting floors are often loud, dirty, and include physically laborious work; in a word – unattractive. And while the analog experts are starting to age and retire, converters find themselves struggling to find skilled employees to replace them and are looking for automation wherever they can.

Digital printing includes automated workflows that control production and reduces the need for craftsmen operators. Offering a modern & clean workplace is a bonus. HP True Water-Based ink technology, support a clean and safe environment for employees. In addition, the HP presses come with various digital workflow integration solutions and with HP PrintOS, a cloud-based technology that can be used for simplifying operator work and for managerial reports.

Improving bottom line

Investing in new technology, always, and especially in turbulent times, is perceived as a risk. But with every risk there’s also an opportunity. Digital print for packaging helps converters expand their reach to both smaller brands and larger brands.

With fast time to market and shorter run lengths, small brands do not need to commit to quantities beyond their actual reach and take risks on production batches that are not economical using traditional analog processes.

Large brands can enjoy an improved service level from a converter who adds digital print capabilities. As mass production is here to stay, long runs will continue to run on analog, but with digital taking up all the medium to short runs, the converter can now utilize the analog equipment much more effectively and take on even more long run jobs.

Looking ahead

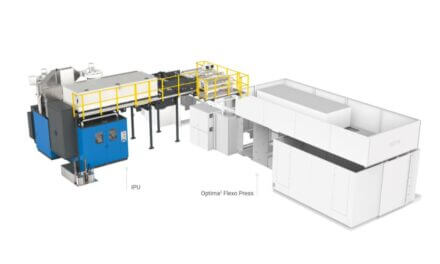

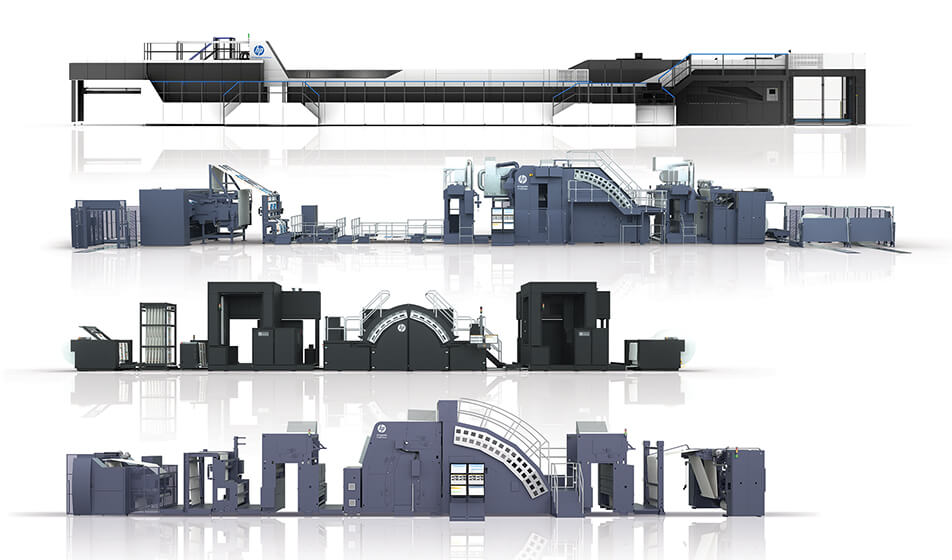

With HP Corrugated sheet-fed and web-fed digital printing solutions, converters no longer need to choose between improving their bottom line via production efficiencies or growing their top line via high-quality value-added services and products. Converters can now provide a whole new level of service to brands to grow their business, while maintaining the highest quality, and keeping production efficient to ensure overall profitability.

As converters and brands endeavor to successfully manage the volatility in demand and adapt to evolving consumer behavior, embracing digital print technologies can be just the right medicine in these uncertain times.

The Author

The Author

Adi Relles-Shorer, Product and Strategy Manager, HP PageWide Industrial