What are the critical issues encountered by printing companies and the points of improvement of existing technologies in solvent management? We talk about it with EPC, as the company launches on the market its latest innovation, subject to HRTTM patent, for the recovery of solvents and inert gas activated carbons regeneration.

The flexible packaging printing sector is currently facing significant challenges related to solvent management, with an increasing focus on economic sustainability, in terms of reducing operating costs, and environmental issues due to more stringent pollution regulations.

The data regarding solvent recovery

From the analyses carried out on the data of our last survey, a picture emerges in which a considerable part of solvent recovery plants in use have a high average age. In fact, of the companies that responded, 33.4% declared their plant was built before 2000, more than 16% even before 1990. This situation shows how technologically lacking plants combined with the high costs of raw materials such as electricity and natural gas, result in high energy consumption and significant operating costs. In this context, therefore, companies see solvent recovery facilities as a strategic operational and financial lever: 75.06% confirm energy consumption and operating costs as the main critical issues, followed by maintenance difficulties and availability of spare parts.

This data show how many plants in use are now outdated: however, companies that do not have a solvent recovery plant show a different perception of the problem. Although 50% of companies without a plant consider it important, solvent recovery is not yet seen as a priority strategy, energy consumption and operating costs are seen as responsible for considering it not a primary need (57%). At the same time, however, if investments were made, the main motivations would be the reduction of VOC emissions (42%) and the amount of solvent recovered (57%). This confirms that the functional costs of operating a plant are the greatest criticality found and perceived, while compliance with quality and environmental limits and the solvent recovered to be reused in production are the greatest benefits pursued.

EPC solutions

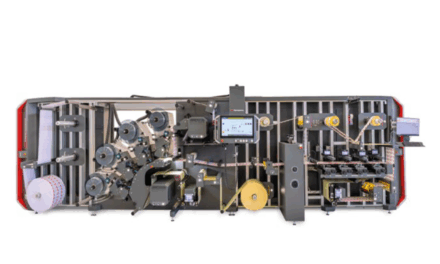

Looking to the future of the flexible packaging printing industry, EPC proposes itself to the industry with an innovative technological solution capable of balancing energy consumption at sustainable operating costs, customisation of the installation and practicality of maintenance with the regeneration of the inert gas activated carbon bed. The patented HRTTM Heat Recovery Technique technology aims to significantly reduce solvent recovery costs and improve energy efficiency by accelerating the return on investments thanks to a reduced cost of recovered solvent.

With this new technology, EPC stands out as a response to the obsolescence and inefficiency of standard technologies. We delved into the subject with Eng. William Boarolo, General Manager of EPC.

“The key in EPC has been the experience gathered in the era of standard inert gas regeneration technology recovery plants. We have spent many hours of research and development on existing plants, following our vision: apply to existing plant technologies already installed on much more complex plants, which include sophisticated and technologically advanced equipment, to speed up the regeneration of the activated carbon beds.

Our technology, thanks to the overlaying regeneration sequences carried out simultaneously, as opposed to standard technology, and to energy and heat recovery in the regeneration circuit, has allowed us to drastically reduce operating costs of recovery plants by 40%, while increasing abatement efficiency. With the same activated carbon, we recover more solvent with less environmental impact. This allows us to put on the market systems that, despite having a purchase cost comparable to those based on standard technology, allow for greater efficiency of abatement and recovery as well as unattainable operating performance “.

High-performance systems: same initial investment, unique efficiency in the sector.