Breaking the mold: Siegwerk’s NC-free solutions for futureproof flexible packaging.

LORENZO FOSCHI, Managing Director Siegwerk Italy

As the packaging industry faces increasing pressure to improve recyclability in line with a circular economy, traditional nitrocellulose (NC)-based inks and coatings are coming under scrutiny. NC has long been a valued binder for solvent-based packaging printing. However, despite many advantages, such as high resistance, fast drying, and excellent adhesion, NC-based inks also pose significant challenges for sustainability and safety.

NC in inks: The pressure is rising

NC’s lower thermal stability presents a risk in storage and handling, especially considering rising global temperatures. Besides, the presence of NC in inks can significantly hinder the recycling process, especially for plastic packaging. For example, NC-based inks can cause unpleasant odors and discoloration, leading to a lower mechanical strength of the recyclates and thus to a reduced film quality.

As a result, more and more stakeholders along the value chain have already adapted or intend to adapt their regulations for polyolefin packaging structures, such as RecyClass and CEFLEX. This will further restrict the use of NC content in packaging, a situation that is likely to be reinforced by the upcoming PPWR. Therefore, moving away from NC is not just a trend but could become an operational necessity. Here, Siegwerk’s NC-free toolbox comes into play offering printers and converters a path forward – enabling the realization of high-performing and recyclable flexible packaging across the full-range of application segments. Originally developed to meet sustainability requirements, the company’s NC-free solutions also represent a robust, high-performing alternative for customers currently facing rising NC costs.

Siegwerk’s NC-free toolbox for flexible packaging

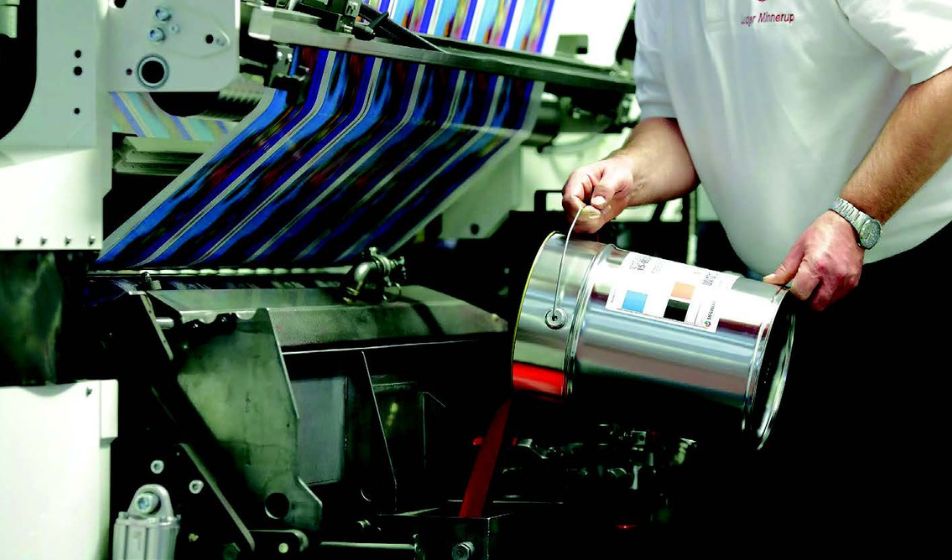

As one of the leading ink experts worldwide, Siegwerk has been offering NCfree inks for a long time. The toolbox now bundles the company’s latest generations of NC-free inks, especially for the realization of recyclable polyolefin-based flexible packaging. It offers customers the full range of color, white, and overprint varnishes for both lamination and surface applications in gravure and flexo printing. All solutions are fully compliant with current recycling guidelines and are available as either ready-to-use ink or masterbatch system.

Thus, Siegwerk’s toolbox enables customers to easily find the right NC-free solution for creating recyclable PE and PP structures without compromising on packaging or process performance. At the heart of Siegwerk’s NC-free innovations is a proprietary polyurethane (PU) resin technology that serves as replacement for nitrocellulose. This new generation of binder not only enables comparable high performance such as excellent printability, high heat and mechanical resistance but also supports safe and easy recycling.

In other words, Siegwerk’s PU binder delivers ink performance on par with NC-based systems, but without the associated downsides in terms of recyclability.

Industry first: NC-free inks for PE and PP films

Among the latest innovations in the toolbox are NC-free alternatives specifically for surface printing on PE and PP. As the first of their kind, these NC-free surface ink systems offer a recyclable alternative with the same technical and mechanical performance as comparable NC-based inks. Industrial applications of the new flexo and gravure surface inks have already shown good sealing and high rub resistance, confirming suitability for surface printing without the use of an additional OPV.

Future-proof flexible packaging

With stricter regulations, rising NC costs, and sustainability as a key competitive factor, Siegwerk’s NC-free toolbox provides a forward-looking solution for printers and converters seeking to stay ahead of the curve. It proves that high-performance packaging doesn’t have to come at the expense of recyclability or safety, further paving the way for circular flexible packaging.