ColorConsulting presents its all-round approach, which always enables the attainment of an excellent result, regardless of the printing technology used.

Each labeling company has different printing technologies at its disposal, in order to meet the different needs of its customers: Digital printing for customization flexibility, Flexographic printing for multi-material management, Screen Printing and Offset printing for high quality. In this varied landscape, it is complex to maintain high standards of color quality because there are many variables that come into play.

ColorConsulting, a company dedicated to consultancy in the field of correct ink color reproduction, supports companies in solving all the problems expressed by the market thanks to a 360° support and the supply of ad hoc products for every need. Our consulting spirit requires us to test and choose every product proposed because it is considered the best for the needs of the end customer and if we do not find what we are looking for… we develop it!

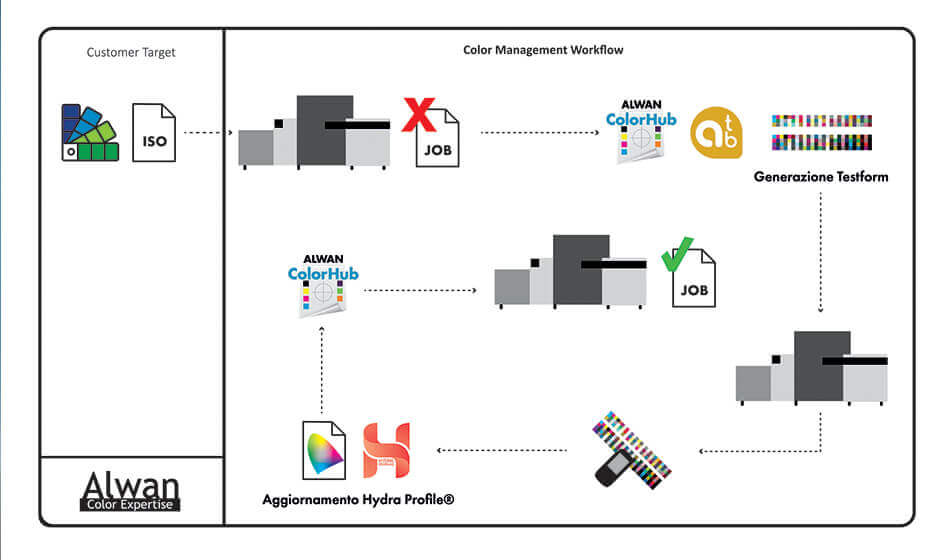

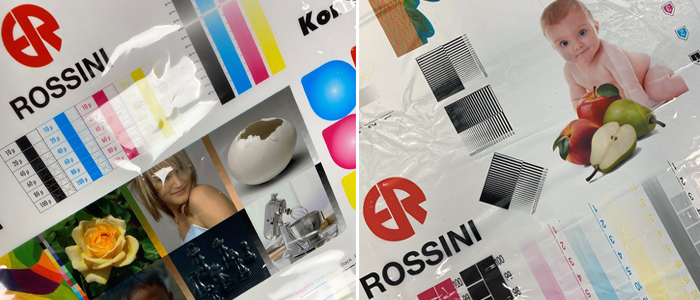

The print file In digital printing a correct color management starts with the print file, and a Color Server that manages the repurposing is the best way to avoid unpleasant surprises. Alwan ColorHub combined with Hydra Profiling® manages not only the profiles of the different devices involved but also TAC and GCR allowing an effective Ink Saving, moreover the new HydraFix® feature automatically and quickly corrects the profiles in relation to possible printing variations.

Managing color When we talk about traditional printing instead, color management is synonymous with ink management and passes through the creation, approval and eventual recovery of color recipes. X-Rite InkFormulation offers the best possible prediction of the final result, quickly calculating the most effective recipe from the point of view of cost and desired result.

The flow of inks At this point all that remains is to manage the weighing of the inks thanks to InkWeigh, a solution developed by ColorConsulting that manages the inks in their entirety: from the first formulation, to the management of the warehouse through the reuse of returns in formulation with colorimetric method or mathematical calculation, all while keeping track of the production lots used.

Quality control We conclude our proposal of effective workflow with the quality control of ColorTrack QualityTrack and ColorAnalytics that allow you to keep the production under control, analyzing the problems in relation to the events in the press room (change anilox / reel / correction / …) and allow the export of customized reports as well as the ability to connect with the company management for a 4.0 style process.