Inglese Srl is present at Labelexpo Europe (Hall 3 Stand E72) with its complete solutions for label and flexible packaging fields with its important Partners: Toray Industries Inc., DuPont™ Cyrel®, Esko-Graphics B.V., REFINE Finishing A/S, Breit-Technologies llc. and Azul Sistemi.

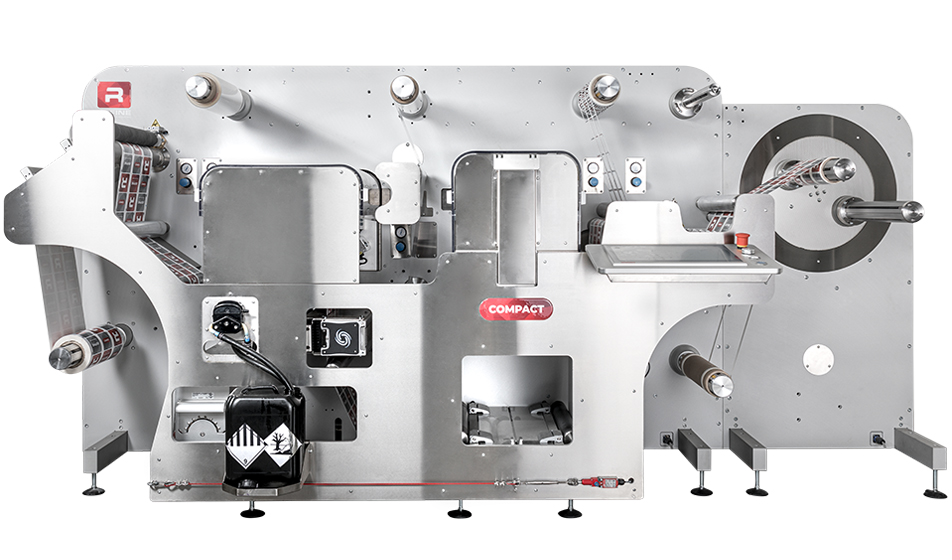

At the international fair, Inglese Srl relaunches its solid partnership with REFINE Finishing, as emphasized by Marcello Morara, Commercial Director at Inglese Srl, via live demonstrations on COMPACT 2 17” finishing machine. It is a complete system, equipped with: semi-rotary flexographic station, Corona treatment, UV-led system, cold lamination unit, semi-rotary die-cutting and semi-automatic turret which increases productivity up to 2 times. All machines in the COMPACT line are equipped with energy saving solutions and fully comply with 4.0 requirements, and are designed to easily be integrated into a digital workflow.

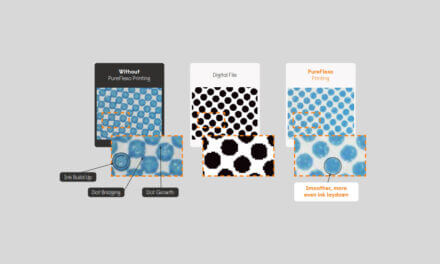

Looking for “green” embellishment with eye-catching effects for your packaging?

In Brussels, visitors to Inglese Srl stand will also be able to see and touch the innovative, eco-friendly Breit-Technologies’ Cast and Cure™ decorative coating process. Thanks to the special “micro-embossing” technology with which they are produced, the patterns on Cast and Cure™ films are applied without the need for lamination to the printed substrate, which thus maintains its original recyclability and/or compostability properties. This way films can be reused over and over again and are compatible with standard cold foil systems and UV varnishes without requiring any change to the existing production process and allowing for significant waste reduction. Moreover, neither glues nor solvent-based varnishes are used for Cast and Cure™ applications, so this is a VOCs free system. Made of 100% PP, once their function is exhausted the films are fully recyclable as plastic waste. Cast and Cure™ films from Breit-Technologies are available in various patterns to achieve great visual impact, holographic or textured, soft touch matt and extra-clear. The films also lend themselves well to protective and anti-counterfeiting applications, such as micro-texts printing.

Breaking news for anilox cleaning

At its 3 E72 stand, Inglese will present its brand new INGLESE AC-J series anilox cleaning machines. This system for high-pressure water washing is particularly designed for frequent colour changes and is suitable for both geared anilox and sleeves, 800 mm to 2000 mm (narrow web and wide web processing). Machines of the AC-J series are available in different formats for the cleaning of 1 to 4 simultaneously, depending on the model, are controlled by PLC and equipped with water and detergent recirculation systems. These features put in place a closed-cycle processing, which allows to reuse both the water and cleansing agent several times until they lose efficiency. In addition, it allows to select the duration of the detergent cycle and determine the precise length of the anilox cylinders and sleeves; making it possible to accurately calculate the time the washing process requires and eliminating any waste. Among the optional features, the PLC managed automatic liquids discharge system is particularly useful. In addition, on request, the 4.0 Industry set up can be implemented, with a dedicated PLC, touch panel and pre-set to be connected to the customer’s

Find out more about Inglese Srl, its important partnership and consolidated range of equipment at https://www.inglesesrl.com