Great interest in the market for the new Onyx GO CI flexo printing by Uteco. Presented in world preview at the last K in Duesseldorf, it is characterized by radically revisited processes and components, obtaining start-ups of 3 minutes, 0 waste, and a speed of more than 400 m/min. The very small dimensions (10 m x 5 x 4/h), the compactness of the body composed of only two complementary blocks, the essentiality of the layout that facilitates the job of the operator, the optimization of each individual component… everything introduces a dimension of savings.

Hence the performance with a minus sign and the corresponding with a plus sign: less than 3 minutes for printing pressures and register setup translates into +55% faster setup process and up to 240 extra hours of production/year, with up to 1.8M€ higher revenue. Only 18 meters material waste during setup phase means, the company estimates, saving 200 km/year of material and more than 35,000 euros. On the other hand, more robustness reduces wear and vibrations, ensuring print quality even at the highest process speeds (up to 400 m/min) and lowering noise level, which remains below 80 decibels.

The crucial components

During the design phase, Uteco engineers revisited all the machine’s components, creating new patented solutions that increase the automation, precision and rationality of the various process steps. Among them, the system for cliché’s 3D characteristics recognition automatically transmits information to the relevant components – typically the inking and drying systems – reducing time and errors, and ensuring repeatability of jobs.

Similarly, and with the same objective in mind, the automatic adjustment of printing pressure among the cylinder, cliché and substrate, and the almost instantaneous printing register, with important advantages in terms of maintenance as well. Significant energy savings – up to 50 percent per year – are due to the new patented smart drying system that optimize energy consumption according to the printing characteristics (it use only the drying power needed for each printing unit), assisted by a particularly effective ventilation system (patented).

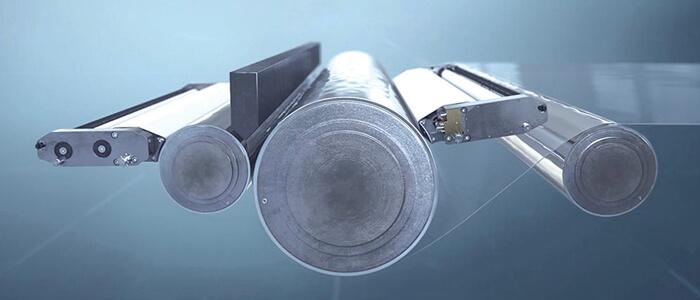

And so is the inking system, that dispenses only the quantity of ink needed to each printing unit; the optimized positioning of its elements optimizes flows, generates energy savings (up to 60 percent). The washing system has also been revisited and reduces solvent consumption (up to 40%), as have the new dynamic doctor blades: very light (less than 10 kg) with low consumption and blades wear.

Ergonomics and versatility

The attention to the operator that the designers kept well in mind when developing the Onyx GO translates into greater comfort and ease of operation of the machine, whose operating space is all packed into 50 sqm. Again, a sum of factors contributes to the result: the interactive, adaptive cockpit allows monitoring and management of data in real time; drying box (and more generally, components to be replaced) are easily removed with a single move and without effort; access to the central drum for cleaning and maintenance is easy and direct; the upper part of the machine accessible by means of a catwalk extended to the total length of the machine…

To further simplify work and optimize print quality, there are even small but relevant details such as the creation of fully removable and upgradable drying box, with nozzles of different shapes, to be chosen according to the specific needs of the process at hand. Onyx GO processes all types of materials, with water- and solvent-based inks, and is easily configured for different types of work through special predefined kits. Three printing widths: 800, 1000 and 1320 mm.