In this in-depth analysis by Stefano D’Andrea, we discover how to understand the interactions between materials and system components in order to better manage the flexographic process.

Flexography is one of the most stable, repeatable, reliable and predictable systems that modern technology offers to printing enterprises. That is, as long as the specifications are known in advance and production is organized according to known rules. Achieving high quality and consistent print results requires mastery and compliance with the rules governing the printing process, as well as a solid technical training.

In fact, flexography offers considerable potentialities that can only be fully exploited through the rigorous application of an appropriate methodology. This potential has made flexography a protagonist in the world of packaging (almost 50% of global production comes from flexography) and has granted its continuous growth.

Materials are crucial for success in production and, unlike other systems, in flexography it is essential to be aware of interactions between different materials and the given printing system, even before starting production.

The importance of calibration and control

One of the fundamental aspects to ensure a stable flexographic printing process is the correct calibration of the system. This involves a methodical approach that includes optimization, fingerprinting, process control, characterization, and continuous improvement.

Calibration has the fundamental objective of establishing a stable and repeatable printing condition, which allows for printing system settings based on measurable and verifiable parameters. All characteristics and variables of the components and materials involved in the printing group contribute to determining this condition, which must remain constant. When production involves the use of different materials or components, a specific printing condition must be defined for each of them.

Once this condition has been identified, all related prepress processes can be carried out, thus guaranteeing predictable and consistent results.

The importance of data

The printing condition is defined through the characterization data, which numerically represent the rendering of color of the printing system. These data, obtained through careful calibration, are essential to ensure operational control during production.

They constitute the reference values necessary for the management of the process, serve as a basis for the creation of color profiles intended for primary colors identification and are fundamental for carrying out color tests to simulate the final result. Summarizing, the first step is to note how the system reproduces colors, based on this information the prepress operations are then carried out and finally printing is performed under the same conditions that produced the characterization data.

Disposing of characterization data relating to a specific printing condition allows to effectively monitor the entire production process. Ideally, a characterization profile should be available for each printing condition; however, after careful analysis, groupings can be made where appropriate.

An important advantage: ink stability

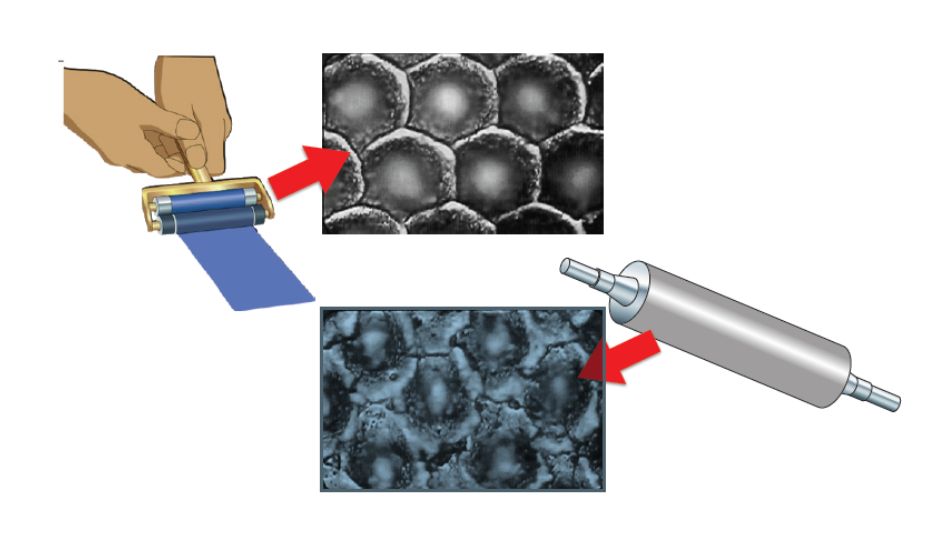

One of the main advantages of the flexographic system is its strategic relevance in terms of consistency and predictability of printing results: the inking system, based on the anilox roller, allows the transfer of a constant and accurate amount of ink. However, this result is only guaranteed when the system is correctly calibrated. In fact, unlike other printing methods such as typography or offset, flexography does not allow direct adjustment of the amount of ink transferred to the plate during production.

To vary the ink delivery in the flexographic process, it is necessary to replace the anilox roller or, if required, modify the texture characteristics of the plate surface, which, however, calls for the replacement of the plate. Similar limitations are found in rotogravure printing, which requires the replacement of the matrix cylinder, and in digital printing, which requires a new digital file. For this reason, any changes must be communicated in advance.

The management of variables and new materials

Before starting the production phases, and after completing system calibration and defining the characterization data, it is essential to verify that all components and products employed in the process have the same characteristics as those used during calibration. This ensures conformity in the final print result. However, discrepancies may occur due to normal wear, accumulation of impurities, need for maintenance or the use of materials with different specifications. Below are some details related to the main printing system components.

Anilox roller

Consequently, if roller replacement becomes necessary, it is essential to ensure that the new anilox complies with all the technical specifications of the previous model, in order to maintain high standards of consistency and quality in the printing results. An inventory of anilox rollers with homogeneous volume and linearity specifications for each application (process or spot colors, large surfaces) is essential. Ensuring that the employed anilox matches the one used for ink formulation, especially when using spot colors is crucial.

A misalignment at this stage will easily lead to continuous corrections in printing. Having a large number of rollers with different specifics indicates that the system is not working with known and predetermined printing conditions, and entails chasing the wanted result by stopping the machine and changing the anilox roller. Moreover, the significant economic investment required to mantain an extremely large anilox inventory means ignoring the benefit of the ink stability provided by the flexographic technology.

The Pressor

Materials and substrates

Inks

Prevention is better than cure

Every variable involved in the printing process follows a predictable pattern, characterised by a correlation between time and performance. Initially, performance remains constant, but tends to decline progressively over time. Taking action only when critical thresholds are reached leads to increased costs, downtime and reduced operational efficiency. It is therefore essential to closely monitor the evolution of variables, define specific acceptance levels and plan corrective actions

before a significant deterioration in performance occurs.

This approach must be implemented both during the calibration phase, as part of the fingerprinting process, and through the enforcement of characterisation data by means of systematic process control.

It is essential that checks and verifications on incoming materials are carried out promptly before production starts. Characterisation data, when obtained through a monitored and regularly maintained system, is reliable and representative of the state of the printing process. This information allows the pre-press department to operate with predictability and achieve the set quality standards.