In flexography, the management of materials is a determining factor for the efficiency and quality of the entire production cycle. Each stage of the process – from pre-press to printing and finishing – is directly affected by the characteristics and conditions of substrates, inks and plates.

Francesco Maria Costanzo, Pre-press Manager Poplast Group

In particular, pre-press is the critical point where choices of materials have the greatest impact on the final yield: the correct selection of the substrate, the chemical physical compatibility of inks and the quality of the printing plates affect not only colour accuracy and detail definition, but also process stability in all subsequent phases. Accurate and methodical material management reduces waste, prevents defects and guarantees production uniformity, laying the foundations for a reliable, high performance flexographic printing that complies with the standards required by the customer.

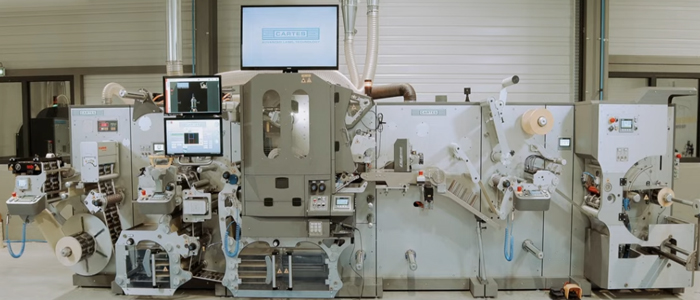

Some companies have done research on this, experimented with solutions and modified their approach to pre-press, obtaining tangible results that express the full potential of production technologies. We asked Francesco Maria Costanzo, Pre-press Manager at Gruppo Poplast, for his opinion on this topic and to delve into the results the company obtained through an approach based on experimentation.

Material management is a crucial aspect: how much does it affect pre-press work and how do you organise it, especially in the case of reprints?

Material management is a decisive element in the organization of pre-press work, especially when it comes to ensuring the repeatability of reprints. To ensure consistent results over time, fingerprint tests are performed with characterization equipment that can be replicated at any time.

This is complemented by the definition of supply specifications, in which the agreed specifications determined with our partners are validated and guaranteed through certified analyses of each manufacturing phase. Stability of the process is also monitored through periodic verification tests, that allow us to identify any deviations and promptly intervene. Finally, routine maintenance is planned and integrated directly into the production cycle, so as to ensure operational continuity without negative impacts on quality or pre-press processing times.

What would be your ranking, in order of importance, of the materials that most influence pre-press work in flexography, and for what reasons?

In flexography, when it comes to establishing a classification of the materials that most influence prepress, the structure requested by the customer is undoubtedly the priority element. Which, in fact, includes the printing substrate, the materials intended for lamination and, consequently, the type of inks to be used.

Each choice taken upstream directly affects the prepress process, determining the technical characteristics to comply with, the tolerances to be guaranteed and the measures to take in order to ensure the desired quality of the final result. In this sense, the structure defined by the customer becomes the reference point around which all subsequent operational activities revolve.

Among the most obvious aspects (and often also the feature customers pay more attention to) is that of colour rendering. How do you manage this aspect when changing materials is required?

Colour rendering is certainly one of the most obvious aspects and, at the same time, the most monitored by the clients, especially when facing material changes. To ensure consistency and quality in these situations, a correct characterization of the process is essential. The most suitable photopolymer is selected and its msetting calibrated, the most suitable engraving curve is defined, the right anylox is chosen to ensure the amount of ink and the optimal double-sided adhesive is identified to ensure stability and uniformity.

In this way it is possible to maintain control on the variability introduced by the new material and ensure a colour rendering in line with the customer’s expectations.

On our last visit we noted how innovation and research are pillars of the company’s philosophy. Can you tell us something about the work done in pre-press and the evolution that the department has gone through?

In Poplast’s prepress department, innovation is intertwined with a return to origins. The approach adopted, in fact, is based on the experience we gained as a printing company, now enriched with much more advanced tools than in the past. This allows us to approach all processes with a practical and concrete vision, with a great knowledge of the needs of the printing business, but at the same time with the support of advanced technologies that allow accurate control and predictive management of the processes.

In this balance between tradition and modernity lies the evolution of the department, which continues to grow from a compact station a few years ago to six specialized operators and a workflow that reaches all the way to the machine, for real time data control.