Renowned package printing expert Dr. Kai Lankinen, together with partners UPM and Siegwerk, has validated an innovative water-based barrier varnish printed directly on paper in flexo on a Uteco OnyxGO. Here are the test results.

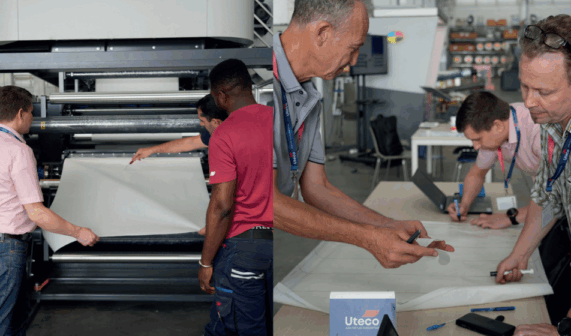

As the packaging industry evolves to meet stricter regulations and rising sustainability demands, new technical solutions are emerging to replace plastic materials. In this context, Dr. Kai Lankinen, together with UPM Specialty Papers and Siegwerk, conducted industrial-scale trials aimed at demonstrating the potential of flexographic printing to print functional barrier coatings directly on paper. The trials were carried out at Uteco’s Demo Center in Verona, Colognola ai Colli, utilizing the Uteco OnyxGO 8-color Flexo Press.

Functional Barriers Varnishes to replace extrusion or lamination

The main goal of the trials was to validate the possibility of applying water-based dispersion barrier coatings via flexographic printing to achieve moisture, oil, and heat-seal resistance directly on paper substrates. By eliminating the need for plastic films or extrusion coatings, this approach offers a more sustainable solution while enabling customization of barrier performance at the printing stage.

The Setup: Real-World Industrial Environment

Testing was conducted under particularly demanding conditions, during very hot summer days, with temperatures reaching nearly 40°C and high humidity levels – a true stress test for water-based systems. The Uteco OnyxGO press ran at high speeds without technical limitations, proving its reliability for such advanced applications.

The tests involved three paper grades from UPM Specialty Papers (Solide™ Lucent, Asendo™, and Asendo™ Pro). Initially, one of these papers did not have any barrier properties, and none featured heatsealability. Siegwerk developed three specialized overprint varnishes (OPVs) from their CIRKIT BAR SEAL range, which were applied in different layer configurations and coating weights to explore a range of barrier effects.

Preliminary Results and Insights

Theoretical sum of anilox volumes used ranged from 12 to 76 ccm, and further laboratory analyses are ongoing to confirm final coating weights and barrier performance. However, even initial results indicated clear improvements in water and oil resistance. All CIRKIT BAR SEAL coatings were compliant for direct food contact, an important requirement for many packaging applications.

Implications for the Industry

This project demonstrated that flexo-printed barrier varnishes on paper are not merely a conceptual possibility but a technically viable, scalable solution ready for industrial production. It offers a promising path to reduce or replace plastic materials in packaging, either an additional layer of plastic film or extrusion coating, helping converters and brand owners meet regulatory and sustainability targets.

Uteco’s Unique Value

Through the availability of its Technical Center, the high-performance OnyxGO flexo press, and technical expertise, Uteco enabled Dr. Lankinen, UPM, and Siegwerk to carry out these complex trials under realistic production conditions. The success of theproject highlights the potential of flexographic technology as a key enabler in the transition toward more sustainable fiber-based packaging solutions.